Series S | Thermodynamic Disc Steam Traps

Steam Traps Series S | Thermodynamic Disc Steam Traps

S31N

Models that handle steam locking also available

Features/Applications

Features

Compact and cost effective design

It has a space saving, simple mechanism with very few moving components.

Easy maintenance

The minimum of moving parts and an easy in-line access ensures easy and fast maintenance.

Special design against steam locking

To avoid cases of steam locking, Miyawaki offers special models to handle steam locking.

(S31N-G/S31NF-G, S31N-2/S31NF-2)Flexible installation

This product can be installed either horizontally or vertically.

Auto blow off and air vent

Thanks to a bimetal ring, the trap smoothly discharges initial air and cold condensate. (Auto blow-off mechanism)

Typical applications

Suitable for steam main lines, small steam equipment, and other such applications.

Dimensions/Weight

Dimensions/Weight

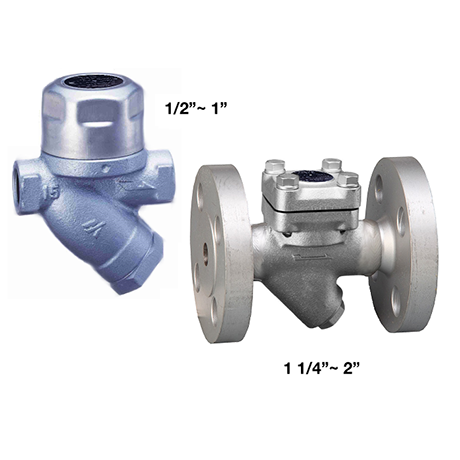

Screwed

½”・¾”・1”

1 ¼”・1 ½”・2”

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| ½” | 90 | 55 | 65 | 60 | 3.5 | 2.2 | 2.6 | 2.4 | 1,1 | 2.4 |

| ¾” | 60 | 2.4 | 1,2 | 2.6 | ||||||

| 1” | 95 | 3.7 | 1,3 | 2.9 | ||||||

| 1 ¼” | 180 | 104 | 100 | 106 | 7.1 | 4.1 | 3.9 | 4.2 | 8,0 | 17.6 |

| 1 ½” | 8,7 | 19.2 | ||||||||

| 2” | 111 | 4.4 | 9,3 | 20.5 | ||||||

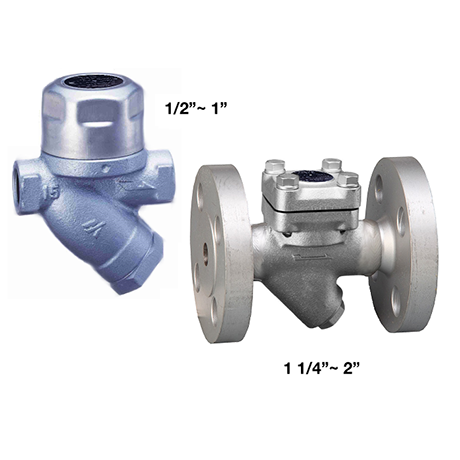

Flanged

½”・¾”・1”

1 ¼”・1 ½”・2”

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| ½” | 140 | 55 | 65 | 60 | 5.5 | 2.2 | 2.6 | 2.4 | 2,5 | 5.5 |

| ¾” | 150 | 60 | 5.9 | 2.4 | 3,0 | 6.6 | ||||

| 1” | 160 | 6.3 | 4,2 | 9.2 | ||||||

| 1 ¼” | 240 | 104 | 100 | 106 | 9.5 | 4.1 | 3.9 | 4.2 | 12,0 | 26.4 |

| 1 ½” | 13,5 | 29.8 | ||||||||

| 2” | 14,5 | 32.0 | ||||||||

Specifications

| Model | Connection |

Max. operating pressure |

Max. operating pressure differential |

Max. operating temperature |

Body material |

||||

| Type | Size |

PMO (MPa) |

PMO (psig) |

⊿PMX (MPa) |

⊿PMX (psig) |

TMO (℃) |

TMO (℉) |

||

| S31N |

Screwed Rc,NPT |

½” | 1,6 | 230 | 1,6 | 230 | 220 | 428 |

Ductile cast iron FCD450 |

| ¾” | |||||||||

| 1” | |||||||||

| 1 ¼” |

Cast iron FC250 |

||||||||

| 1 ½” | |||||||||

| 2” | |||||||||

| S31NF |

Flanged FF,RF* |

½” |

Ductile cast iron FCD450 |

||||||

| ¾” | |||||||||

| 1” | |||||||||

| 1 ¼” |

Cast iron FC250 |

||||||||

| 1 ½” | |||||||||

| 2” | |||||||||

*Available flange standards: ASME/JPI 150lb, 300lb, DIN PN16, JIS 10K, 16K, 20K. ASME/JPI 300lb not available for size 2”.

●Maximum allowable pressure (PMA): 1,6MPa (230psig) PMA is the pressure that can be tolerated by pressure-resistant parts (body).

●Maximum allowable temperature (TMA): 220℃ (428℉) TMA is the temperature that can be tolerated by pressure-resistant parts (body).

●Min. operating pressure differential (⊿PMN): 0,03MPa (4.4psig) ⊿PMN is the minimum operating pressure differential between the trap inlet and outlet.

*Special design models against steam locking are available.

| Model | S31N-G | (Screwed) |

| S31NF-G | (Flanged) | |

| S31N-2 | (Screwed) | |

| S31NF-2 | (Flanged) |

Discharge Capacity

Download

* Membership registration is required to download the documents.

Features

Compact and cost effective design

It has a space saving, simple mechanism with very few moving components.

Easy maintenance

The minimum of moving parts and an easy in-line access ensures easy and fast maintenance.

Special design against steam locking

To avoid cases of steam locking, Miyawaki offers special models to handle steam locking.

(S31N-G/S31NF-G, S31N-2/S31NF-2)Flexible installation

This product can be installed either horizontally or vertically.

Auto blow off and air vent

Thanks to a bimetal ring, the trap smoothly discharges initial air and cold condensate. (Auto blow-off mechanism)

Typical applications

Suitable for steam main lines, small steam equipment, and other such applications.

Dimensions/Weight

Screwed

½”・¾”・1”

1 ¼”・1 ½”・2”

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| ½” | 90 | 55 | 65 | 60 | 3.5 | 2.2 | 2.6 | 2.4 | 1,1 | 2.4 |

| ¾” | 60 | 2.4 | 1,2 | 2.6 | ||||||

| 1” | 95 | 3.7 | 1,3 | 2.9 | ||||||

| 1 ¼” | 180 | 104 | 100 | 106 | 7.1 | 4.1 | 3.9 | 4.2 | 8,0 | 17.6 |

| 1 ½” | 8,7 | 19.2 | ||||||||

| 2” | 111 | 4.4 | 9,3 | 20.5 | ||||||

Flanged

½”・¾”・1”

1 ¼”・1 ½”・2”

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| ½” | 140 | 55 | 65 | 60 | 5.5 | 2.2 | 2.6 | 2.4 | 2,5 | 5.5 |

| ¾” | 150 | 60 | 5.9 | 2.4 | 3,0 | 6.6 | ||||

| 1” | 160 | 6.3 | 4,2 | 9.2 | ||||||

| 1 ¼” | 240 | 104 | 100 | 106 | 9.5 | 4.1 | 3.9 | 4.2 | 12,0 | 26.4 |

| 1 ½” | 13,5 | 29.8 | ||||||||

| 2” | 14,5 | 32.0 | ||||||||

| Model | Connection |

Max. operating pressure |

Max. operating pressure differential |

Max. operating temperature |

Body material |

||||

| Type | Size |

PMO (MPa) |

PMO (psig) |

⊿PMX (MPa) |

⊿PMX (psig) |

TMO (℃) |

TMO (℉) |

||

| S31N |

Screwed Rc,NPT |

½” | 1,6 | 230 | 1,6 | 230 | 220 | 428 |

Ductile cast iron FCD450 |

| ¾” | |||||||||

| 1” | |||||||||

| 1 ¼” |

Cast iron FC250 |

||||||||

| 1 ½” | |||||||||

| 2” | |||||||||

| S31NF |

Flanged FF,RF* |

½” |

Ductile cast iron FCD450 |

||||||

| ¾” | |||||||||

| 1” | |||||||||

| 1 ¼” |

Cast iron FC250 |

||||||||

| 1 ½” | |||||||||

| 2” | |||||||||

*Available flange standards: ASME/JPI 150lb, 300lb, DIN PN16, JIS 10K, 16K, 20K. ASME/JPI 300lb not available for size 2”.

●Maximum allowable pressure (PMA): 1,6MPa (230psig) PMA is the pressure that can be tolerated by pressure-resistant parts (body).

●Maximum allowable temperature (TMA): 220℃ (428℉) TMA is the temperature that can be tolerated by pressure-resistant parts (body).

●Min. operating pressure differential (⊿PMN): 0,03MPa (4.4psig) ⊿PMN is the minimum operating pressure differential between the trap inlet and outlet.

*Special design models against steam locking are available.

| Model | S31N-G | (Screwed) |

| S31NF-G | (Flanged) | |

| S31N-2 | (Screwed) | |

| S31NF-2 | (Flanged) |

* Membership registration is required to download the documents.