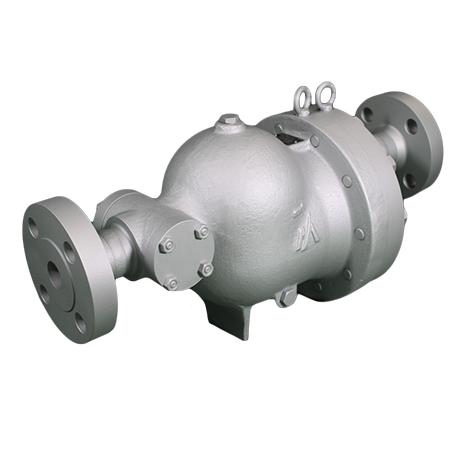

Series G | Ball Float Steam Traps

Steam Traps Series G | Ball Float Steam Traps

GWH70

Features/Applications

Features

Suitable for medium capacity steam processes

Capable of moving continually to change the degree of valve opening according to the incoming condensate to provide maximum heat exchange capacity.

High discharge capacity

A double-port balanced valve is adopted to discharge larger capacity with a smaller body.

Easy maintenance

Internal screen can be taken out quickly and easily without removal of trap from pipe line.

Countermeasure against erosion

Use of stainless steel components at the outlet which is subjected to erosion by the condensate flow.

Condensate recovery

With its high degree of back pressure tolerance, this model supports condensate recovery.

Quick startup

Internal thermostatic air vent automatically discharges of air/gases and cold condensate during startup.

Typical applications

Suitable for high pressure process equipment

Dimensions/Weight

Dimensions/Weight

Socket Weld

| Size | Dimensions (mm) | Dimensions (in.) | Maintenance space (mm) |

Maintenance space (in.) |

Weight | |||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | E1 | E2 | E1 | E2 | kg | lb | |

| 1½" | 480 | 140 | 190 | 290 | 18.9 | 5.5 | 7.5 | 11.4 | 110 | 110 | 4.3 | 4.3 | 62 | 137 |

| 2” | ||||||||||||||

*Standards ASME B16.34 Class900, JIS sch 160

Butt Weld

| Size | Dimensions (mm) | Dimensions (in.) | Maintenance space (mm) |

Maintenance space (in.) |

Weight | |||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | E1 | E2 | E1 | E2 | kg | lb | |

| 1½" | 480 | 140 | 190 | 290 | 18.9 | 5.5 | 7.5 | 11.4 | 110 | 110 | 4.3 | 4.3 | 62 | 137 |

| 2” | ||||||||||||||

*Standards ASME B16.25 Sch160, JIS sch 160

Flanged

Flanged standard ASME/JPI, JIS

| Size | Dimensions (mm) | Dimensions (in.) | Maintenance space (mm) | Maintenance space (in.) | Weight | |||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | E1 | E2 | E1 | E2 | kg | lb | |

| 1½" | 630 | 140 | 190 | 290 | 24.8 | 5.5 | 7.5 | 11.4 | 110 | 110 | 4.3 | 4.3 | 75 | 165 |

| 2” | 85 | 187 | ||||||||||||

*Standards ASME/JPI Class600, Class900, JIS 40K, 63K

Flanged standard PN40, PN63

| Size | Dimensions (mm) | Dimensions (in.) | Maintenance space (mm) | Maintenance space (in.) | Weight | |||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | E1 | E2 | E1 | E2 | kg | lb | |

| 1½" | 630 | 140 | 190 | 290 | 24.8 | 5.5 | 7.5 | 11.4 | 110 | 110 | 4.3 | 4.3 | 72 | 159 |

| 2” | ||||||||||||||

*Standards PN40, PN63

Customized face-to-face dimensions on request.

Please contact MIYAWAKI for further information.

Specifications

|

Model |

Connection |

Max. operating |

Max. operating |

Max. operating |

Body |

||||

|

Type |

Size |

PMO (MPa) |

PMO (psig) |

PMX (MPa) |

PMX (psig) |

TMO (℃) |

TMO (℉) |

||

|

GWH70-W |

Socket Weld* |

1½" |

6.5 |

943 |

6.5 |

943 |

425 |

797 at |

Cast steel |

|

2” |

|||||||||

|

GWH70-BW |

Butt Weld* |

1½" |

|||||||

|

2” |

|||||||||

|

GWH70-F |

Flanged* |

1½" |

|||||||

|

2” |

|||||||||

*Available Standards

|

Socket Weld |

ASME B16.34 Class900, JIS sch 160 |

|

Butt Weld |

ASME B16.25 Sch160, JIS Sch 160 |

|

Flanged |

ASME/JPI Class600, Class900, JIS 40K, 63K, PN40, PN63 |

●Maximum allowable pressure (PMA): 6,5 MPa (psig)

●Maximum allowable temperature (TMA): 425℃ (797 ℉) at 6,5MPa (751 psi)

Maximum operating range of pressure and temperature

(Body design condition: PN63)

・PMO: 6,5MPa at 425 ℃

・TMO: 425℃ at 6,5MPa

Discharge Capacity

Option

Option

Thermal Insulation Cover (Customized manufacturing)

ーTop class insulation performance and Energy savingー

※ Please check Thermal Insulation Cover for further information.

Download

* Membership registration is required to download the documents.

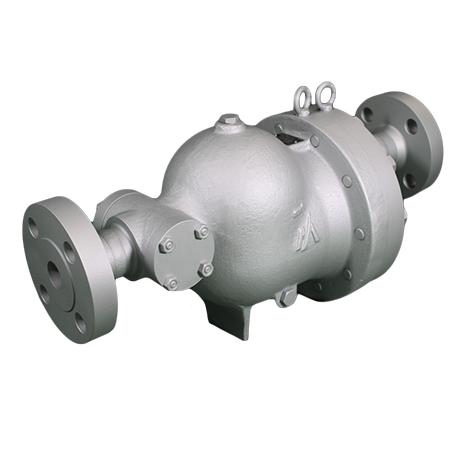

Features

Suitable for medium capacity steam processes

Capable of moving continually to change the degree of valve opening according to the incoming condensate to provide maximum heat exchange capacity.

High discharge capacity

A double-port balanced valve is adopted to discharge larger capacity with a smaller body.

Easy maintenance

Internal screen can be taken out quickly and easily without removal of trap from pipe line.

Countermeasure against erosion

Use of stainless steel components at the outlet which is subjected to erosion by the condensate flow.

Condensate recovery

With its high degree of back pressure tolerance, this model supports condensate recovery.

Quick startup

Internal thermostatic air vent automatically discharges of air/gases and cold condensate during startup.

Typical applications

Suitable for high pressure process equipment

Dimensions/Weight

Socket Weld

| Size | Dimensions (mm) | Dimensions (in.) | Maintenance space (mm) |

Maintenance space (in.) |

Weight | |||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | E1 | E2 | E1 | E2 | kg | lb | |

| 1½" | 480 | 140 | 190 | 290 | 18.9 | 5.5 | 7.5 | 11.4 | 110 | 110 | 4.3 | 4.3 | 62 | 137 |

| 2” | ||||||||||||||

*Standards ASME B16.34 Class900, JIS sch 160

Butt Weld

| Size | Dimensions (mm) | Dimensions (in.) | Maintenance space (mm) |

Maintenance space (in.) |

Weight | |||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | E1 | E2 | E1 | E2 | kg | lb | |

| 1½" | 480 | 140 | 190 | 290 | 18.9 | 5.5 | 7.5 | 11.4 | 110 | 110 | 4.3 | 4.3 | 62 | 137 |

| 2” | ||||||||||||||

*Standards ASME B16.25 Sch160, JIS sch 160

Flanged

Flanged standard ASME/JPI, JIS

| Size | Dimensions (mm) | Dimensions (in.) | Maintenance space (mm) | Maintenance space (in.) | Weight | |||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | E1 | E2 | E1 | E2 | kg | lb | |

| 1½" | 630 | 140 | 190 | 290 | 24.8 | 5.5 | 7.5 | 11.4 | 110 | 110 | 4.3 | 4.3 | 75 | 165 |

| 2” | 85 | 187 | ||||||||||||

*Standards ASME/JPI Class600, Class900, JIS 40K, 63K

Flanged standard PN40, PN63

| Size | Dimensions (mm) | Dimensions (in.) | Maintenance space (mm) | Maintenance space (in.) | Weight | |||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | E1 | E2 | E1 | E2 | kg | lb | |

| 1½" | 630 | 140 | 190 | 290 | 24.8 | 5.5 | 7.5 | 11.4 | 110 | 110 | 4.3 | 4.3 | 72 | 159 |

| 2” | ||||||||||||||

*Standards PN40, PN63

Customized face-to-face dimensions on request.

Please contact MIYAWAKI for further information.

|

Model |

Connection |

Max. operating |

Max. operating |

Max. operating |

Body |

||||

|

Type |

Size |

PMO (MPa) |

PMO (psig) |

PMX (MPa) |

PMX (psig) |

TMO (℃) |

TMO (℉) |

||

|

GWH70-W |

Socket Weld* |

1½" |

6.5 |

943 |

6.5 |

943 |

425 |

797 at |

Cast steel |

|

2” |

|||||||||

|

GWH70-BW |

Butt Weld* |

1½" |

|||||||

|

2” |

|||||||||

|

GWH70-F |

Flanged* |

1½" |

|||||||

|

2” |

|||||||||

*Available Standards

|

Socket Weld |

ASME B16.34 Class900, JIS sch 160 |

|

Butt Weld |

ASME B16.25 Sch160, JIS Sch 160 |

|

Flanged |

ASME/JPI Class600, Class900, JIS 40K, 63K, PN40, PN63 |

●Maximum allowable pressure (PMA): 6,5 MPa (psig)

●Maximum allowable temperature (TMA): 425℃ (797 ℉) at 6,5MPa (751 psi)

Maximum operating range of pressure and temperature

(Body design condition: PN63)

・PMO: 6,5MPa at 425 ℃

・TMO: 425℃ at 6,5MPa

Option

Thermal Insulation Cover (Customized manufacturing)

ーTop class insulation performance and Energy savingー

※ Please check Thermal Insulation Cover for further information.

* Membership registration is required to download the documents.