Series G | Ball Float Steam Traps

Steam Traps Series G | Ball Float Steam Traps

GC20N

Features

Suitable for steam process lines

The floating mechanism discharges condensate immediately at saturation temperature, preventing condensate stacking up on the primary side. Ideally installed in applications where condensate logging cannot be accepted.

Time shortening to start up

Automatically discharges initial air and cold condensate. The diaphragm air vent follows the saturation temperature and prevents air and steam locking.

Energy saving design

Achieves high sealing performance even in situations with extremely small amounts of condensate and reduces steam loss thanks to a precision polished float and three point support mechanism.

Condensate recovery

With its high degree of back pressure tolerance, this model supports condensate recovery.

Typical applications

Suitable for use in foodstuff devices, cleaning devices, air conditioning devices, and other such applications.

Features

Suitable for steam process lines

The floating mechanism discharges condensate immediately at saturation temperature, preventing condensate stacking up on the primary side. Ideally installed in applications where condensate logging cannot be accepted.

Time shortening to start up

Automatically discharges initial air and cold condensate. The diaphragm air vent follows the saturation temperature and prevents air and steam locking.

Energy saving design

Achieves high sealing performance even in situations with extremely small amounts of condensate and reduces steam loss thanks to a precision polished float and three point support mechanism.

Condensate recovery

With its high degree of back pressure tolerance, this model supports condensate recovery.

Typical applications

Suitable for use in foodstuff devices, cleaning devices, air conditioning devices, and other such applications.

Dimensions/Weight

Screwed

| Size | Dimensions (mm) | Dimensions (in) | Gewicht | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| 1/2” | 120 | 21 | 113 | 86 | 4.7 | 0.8 | 4.4 | 3.4 | 2,4 | 5.3 |

| 3/4” | ||||||||||

| 1” | 2,5 | 5.5 | ||||||||

Flanged

| Size | Dimensions (mm) | Dimensions (in) | Weight (kg) | Weight (lb) | ||||||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | JIS(FF) | JIS(RF) | ASME/JPI(RF) | JIS(FF) | JIS(RF) | ASME/JPI(RF) | |||

| 10K,16K | 20K | 150lb | 300lb | 10K,16K | 20K | 150lb | 300lb | |||||||||

| 1/2” | 175 | 21 | 113 | 86 | 6.9 | 0.8 | 4.4 | 3.4 | 3,8 | 3,9 | 3,4 | 3,8 | 8.4 | 8.6 | 7.5 | 8.4 |

| 3/4” | 195 | 7.7 | 4,2 | 4,3 | 3,9 | 5,0 | 9.3 | 9.5 | 8.6 | 11.0 | ||||||

| 1” | 215 | 8.5 | 5,3 | 5,4 | 4,6 | 5,8 | 11.7 | 11.9 | 10.1 | 12.8 | ||||||

| Size | Dimensions (m) | Dimensions (in) | Weight (kg) | Weight(lb) | ||||||

| L | H1 | H2 | W | L | H1 | H2 | W | |||

| DN15 | 150 | 21 | 113 | 86 | 5.9 | 0.8 | 4.4 | 3.4 | 3,4 | 7.5 |

| DN20 | 3,9 | 8.6 | ||||||||

| DN25 | 160 | 6.3 | 4,6 | 10.1 | ||||||

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

| Modell | Connection |

Max. operating pressure |

Max. operating differential pressure |

Max. operating temperature |

Body material | ||||

| Type | Size | PMO (MPa) | PMO (psig) | ⊿PMX (MPa) | ⊿PMX (psig) | TMO (℃) | TMO (℉) | ||

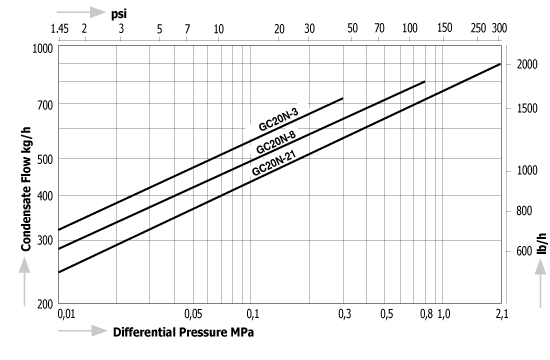

| GC20N-3 | Screwed Rc,NPT |

1/2” |

0,3 |

43 | 0,3 | 43 | 220 | 428 |

Stainless cast steel SCS13A/CF8 |

| 3/4” | |||||||||

| 1” | |||||||||

| GC20N-8 | 1/2” | 0,8 | 116 | 0,8 | 116 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

| GC20N-21 | 1/2” | 2,1 | 305 | 2,1 | 305 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

| GC20N-3F |

Flanged FF,RF |

1/2” | 0,3 | 43 | 0,3 | 43 | |||

| 3/4” | |||||||||

| 1” | |||||||||

| GC20N-8F | 1/2” | 0,8 | 116 | 0,8 | 116 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

| GC20N-21F | 1/2” | 2,1 | 305 | 2,1 | 305 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

*Available flange standards: ASME/JPI, DIN, JIS

●Maximum allowable pressure (PMA): 2,1MPa (305psig) PMA is the pressure that can be tolerated by pressure-resistant parts (body).

●Maximum allowable temperature (TMA): 220℃ (428℉) TMA is the temperature that can be tolerated by pressure-resistant parts (body).

●Maximum operating back pressure (PMOB): 90% of inlet-side pressure

●The discharge line chart shows the discharge rate for condensate with a temperature 6℃ (11℉) lower than the saturation temperature.

* Membership registration is required to download the documents.