-

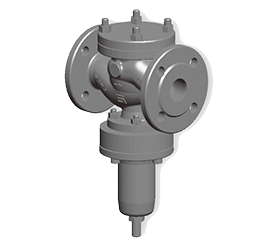

Direct Acting for steam

■Operating principle

Changes in downstream pressure are sensed by the bellows, which expands or contracts depending on the pressure change.

The movement of the bellows will be directly transferred to the spring, which will open or close the main valve, thus keeping the downstream pressure at a certain level.

Suitable for small processes such as sewing, cleaning, food industry, dyeing industry, apparel industry, heating equipment, sterilizer, rubber vulcanizer, medical equipment, bio-related equipment.

● Compact and lightweight design allows installation in tight spaces.

(Model RE2 is the world's smallest steam pressure reducing valve)

-

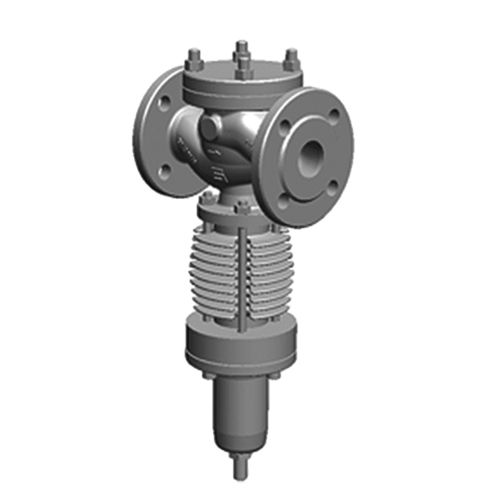

Pilot Operated for steam

■Operating principle

Changes in downstream pressure are sensed by the pilot valve mechanism (bellows connected with a pilot valve unit) through a signal line D, which connects the pilot valve regulator with the secondary pressure side.

Movement of the bellows will open or close the pilot valve, regulating the amount of steam influencing the movement of the piston, which will close or open the main valve, thus keeping downstream pressure on a stable level.

It can be used in a wide range of applications such as food industry, dyeing industry, cleaning industry, apparel industry, heating equipment and air conditioning equipment.

●Energy saving, the more you use it, the more it makes a difference.

micro bellows and a high-precision pilot valve ensures control. (Maximum primary pressure 1.6MPa, maximum pressure reduction ratio 20: 1)

●Excellent durability

Durability is outstanding due to the unique stainless steel micro bellows and overstress prevention mechanism.

-

With Pulse line for steam

■Operating principle

This type is a pressure reducing valve with a downstream pressure sensing

line (pulse line) designed for use of steam. The valve provides a precise downstream

pressure even at changing inlet pressures.

Due to carefully selected springs, a wide range of pressure applications is available.

The valve is very well suited to intermittent or fluctuating loads at the secondary side.

It closes securely when the load on the secondary side will be zero.

● It can be delivered with ductile cast iron, cast steel or stainless steel housings.

● All important internal parts are manufactured in stainless steel. As option the valves can be equipped with a pressure gauge on the valve body.

-

Direct Acting for liquids and gases

■Operating principle

The valve provides a constant downstream pressure at a stable given inlet pressure and constant running flowrates.

Changes in the upstream pressure and fluctuating consumption on the secondary side will result in variations in downstream pressure.

The valve is not designed for dead-end services.

Due to carefully selected springs a wide range of pressure applications is available.

The model REA20 is a direct acting pressure reducing valve designed for use of compressible media, such as air and various gases and for incompressible media such as water, oil and others.

The pressure reducing valve can be delivered with ductile cast iron, cast steel or stainless steel housings.

●All important internal parts are manufactured in stainless steel.

●Soft sealing or metal sealing

Depending on the medium, the valve can be equipped with soft sealing or metal sealing valves/seats. As option, the valves can be equipped with a pressure gauge on the valve body.

-

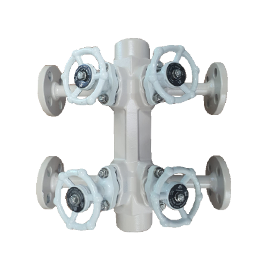

With Pulse line for liquids and gases

■Operating principle

Due to the use of a downstream pressure sensing line (pulse line) the valve provides a constant accurate downstream pressure. Carefully selected springs secure a wide range of downstream pressure applications.

In case of zero consumption on the secondary side the valve closes reliably.

This type is designed for use of compressible media, such as air and various gases and for incompressible media such as water, oil and others.

The pressure reducing valve can be delivered with ductile cast iron, cast steel or stainless steel housings.

●All important internal parts are manufactured in stainless steel.

●The valve is designed for dead-end services.

●Soft sealing or metal sealing valves/seats

Depending on the medium, the valve can be equipped with soft sealing or metal sealing valves/seats.

As option, the valves can be equipped with pressure gauges.