Pumping Traps

Condensate Recovery Devices Pumping Traps

GLP81E

Stainless steel available / Can be used in explosion prevention areas

Features/Applications

Features

Energy saving

Pumping Traps are able to pressure feed low-pressure condensate to high-pressure condensate recovery lines in higher or remote locations. The incorporation of this product enables the previously unused heat energy of condensate to be recovered and efficiently utilized, thus bringing significant benefits in terms of energy saving.

Electricity not required

Pushes condensate out using the pressure of the motive medium*, therefore can easily be installed in ex-proof areas.

No need for additional power grid for remote installations.

*As well as steam, the motive medium can be compressed air, nitrogen gas, or other such gases.

Low filling head

The MIYAWAKI pumping traps have a very low filing head, providing good capacity without the need of higher collectors.

Typical applications

● Recovery of low-pressure condensate (in combination with collectors)

● Support the discharge of condensate from heat exchangers operating close to or below 0 barg

● Stall elimination

*Stall is a phenomenon where the steam trap does not work due to a drop in pressure on the device’s primary side and condensate builds up inside the device. Not only does this prevents the discharge of condensate, it also leads to an increased possibility of water hammer or heat exchanger corrosion occurring.

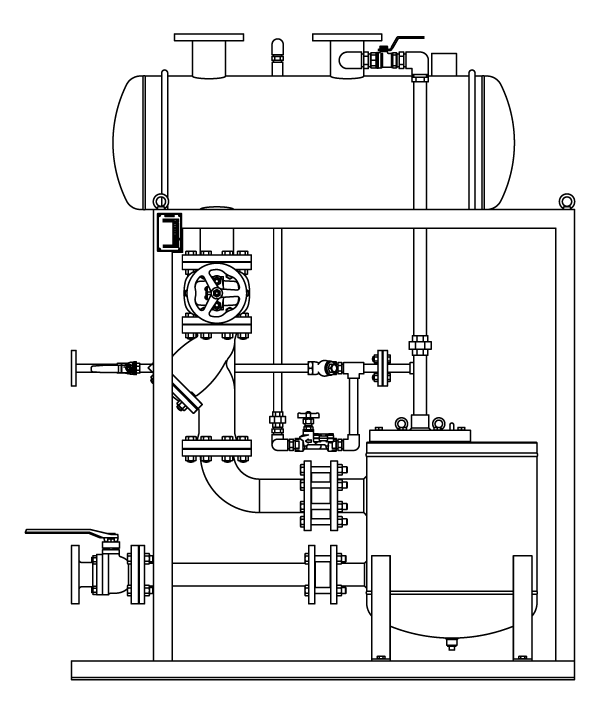

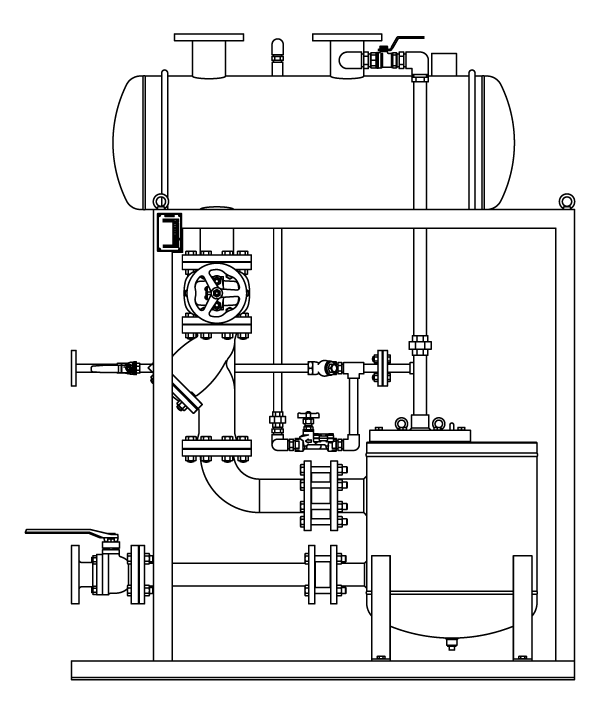

Dimensions/Weight

Dimensions/Weight

| Dimensions (mm) | Maintenance space (mm) | Weight | ||||||||||

| H | H1 | H2 | D | D1 | D2 | W | E | (kg) | ||||

|

669

|

250

|

210

|

554

|

380

|

400

|

457 |

550 or more

|

112 | ||||

| Dimensions (in) | Maintenance space (in) | Weight | ||||||||||

| H | H1 | H2 | D | D1 | D2 | W | E | (lb) | ||||

|

26.3

|

9.8

|

8.3

|

21.8

|

15.0

|

15.7

|

18.0 |

21.7 or more

|

247 | ||||

●The body of the product can also be manufactured using stainless steel.

Also available is the GLP81-PU package unit model that simplifies attachment and installation.

This compact package includes the requisite piping for pumping trap operation.

Specifications

| Model | Connection |

Max. operating pressure |

Max. operating temperature |

Motive medium |

Body material |

|||||

| Size | PMO(MPa) | PMO (psig) | TMO(℃) | TMO(℉) | ||||||

|

Condensate inlet |

Condensate outlet |

Motive medium Inlet |

Exhaust |

|||||||

|

GLP81E |

3" (Flanged*1)

|

2” (Flanged*1)

|

1/2” (Screwed)

|

1” (Screwed)

|

1,05 |

152.25 |

185 | 365 |

Steam/ Compressed air/ Nitrogen gas |

Carbon steel |

*1 Can potentially meet these flange standards: ASME/JPI 150lb, PN16

●Maximum allowable pressure (PMA): 1,6MPa (232psig)

●Maximum allowable temperature (TMA): 185℃ (365℉)

Flow Capacity Chart

| Filling Head | FH-factors | |

| mm | in | |

| 150 | 5.9 | 0,66 |

| 270 | 10.6 | 0,75 |

| 370 | 14.5 | 0,82 |

| 570 | 22.4 | 0,92 |

| 770 | 30.3 | 1,00 |

| 970 | 38.2 | 1,01 |

| 1270 | 50.0 | 1,03 |

the capacity of this chart by the "FH-factors".

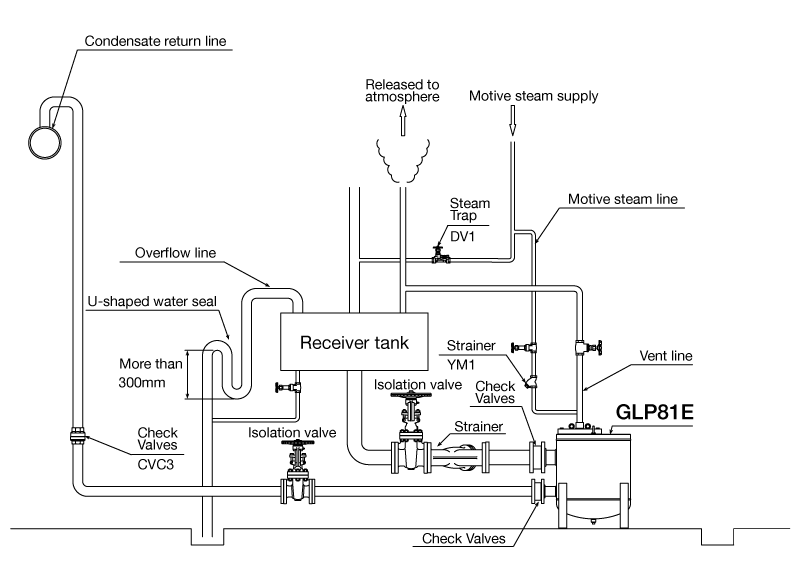

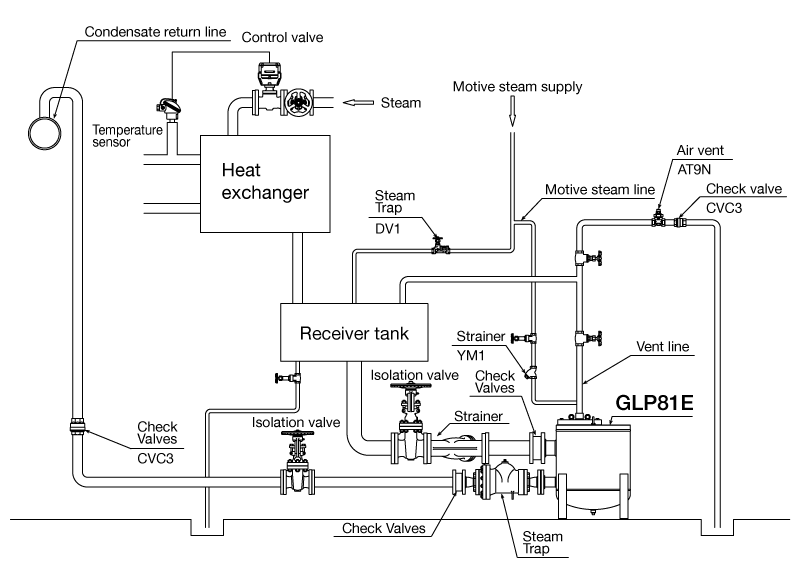

Installation Examples

Open system

Closed system

■Related Products Models for reference

Y strainer YM1

Check valve CVC3

Air vent AT9N AW2

Steam trap DV1

Download

* Membership registration is required to download the documents.

Features

Energy saving

Pumping Traps are able to pressure feed low-pressure condensate to high-pressure condensate recovery lines in higher or remote locations. The incorporation of this product enables the previously unused heat energy of condensate to be recovered and efficiently utilized, thus bringing significant benefits in terms of energy saving.

Electricity not required

Pushes condensate out using the pressure of the motive medium*, therefore can easily be installed in ex-proof areas.

No need for additional power grid for remote installations.

*As well as steam, the motive medium can be compressed air, nitrogen gas, or other such gases.

Low filling head

The MIYAWAKI pumping traps have a very low filing head, providing good capacity without the need of higher collectors.

Typical applications

● Recovery of low-pressure condensate (in combination with collectors)

● Support the discharge of condensate from heat exchangers operating close to or below 0 barg

● Stall elimination

*Stall is a phenomenon where the steam trap does not work due to a drop in pressure on the device’s primary side and condensate builds up inside the device. Not only does this prevents the discharge of condensate, it also leads to an increased possibility of water hammer or heat exchanger corrosion occurring.

Dimensions/Weight

| Dimensions (mm) | Maintenance space (mm) | Weight | ||||||||||

| H | H1 | H2 | D | D1 | D2 | W | E | (kg) | ||||

|

669

|

250

|

210

|

554

|

380

|

400

|

457 |

550 or more

|

112 | ||||

| Dimensions (in) | Maintenance space (in) | Weight | ||||||||||

| H | H1 | H2 | D | D1 | D2 | W | E | (lb) | ||||

|

26.3

|

9.8

|

8.3

|

21.8

|

15.0

|

15.7

|

18.0 |

21.7 or more

|

247 | ||||

●The body of the product can also be manufactured using stainless steel.

Also available is the GLP81-PU package unit model that simplifies attachment and installation.

This compact package includes the requisite piping for pumping trap operation.

| Model | Connection |

Max. operating pressure |

Max. operating temperature |

Motive medium |

Body material |

|||||

| Size | PMO(MPa) | PMO (psig) | TMO(℃) | TMO(℉) | ||||||

|

Condensate inlet |

Condensate outlet |

Motive medium Inlet |

Exhaust |

|||||||

|

GLP81E |

3" (Flanged*1)

|

2” (Flanged*1)

|

1/2” (Screwed)

|

1” (Screwed)

|

1,05 |

152.25 |

185 | 365 |

Steam/ Compressed air/ Nitrogen gas |

Carbon steel |

*1 Can potentially meet these flange standards: ASME/JPI 150lb, PN16

●Maximum allowable pressure (PMA): 1,6MPa (232psig)

●Maximum allowable temperature (TMA): 185℃ (365℉)

| Filling Head | FH-factors | |

| mm | in | |

| 150 | 5.9 | 0,66 |

| 270 | 10.6 | 0,75 |

| 370 | 14.5 | 0,82 |

| 570 | 22.4 | 0,92 |

| 770 | 30.3 | 1,00 |

| 970 | 38.2 | 1,01 |

| 1270 | 50.0 | 1,03 |

the capacity of this chart by the "FH-factors".

* Membership registration is required to download the documents.